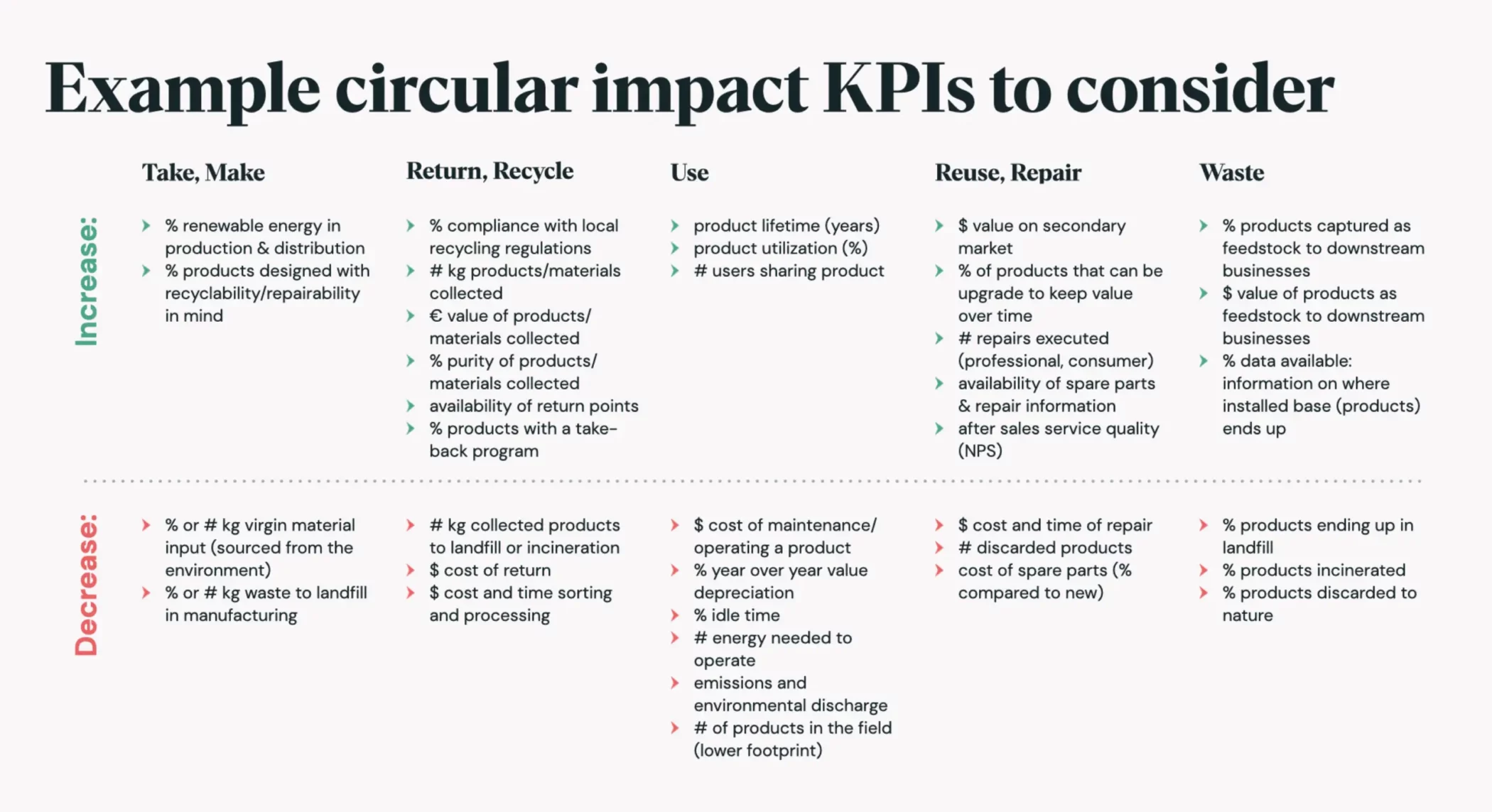

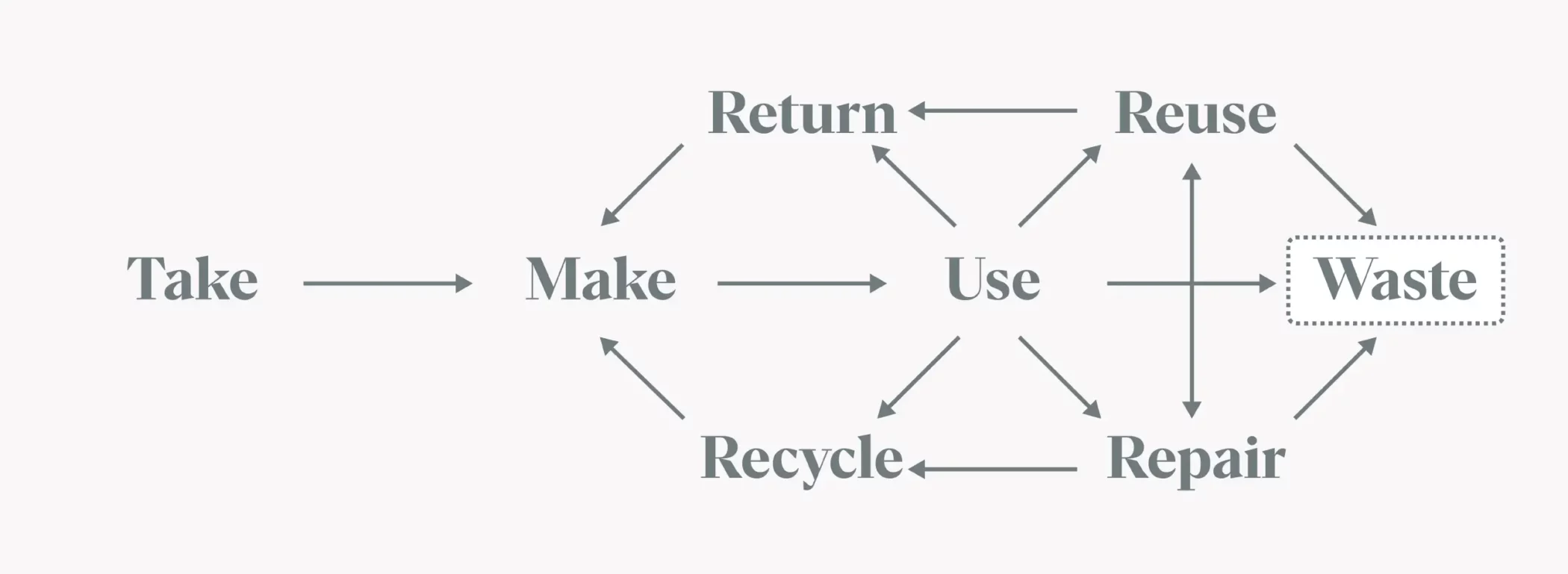

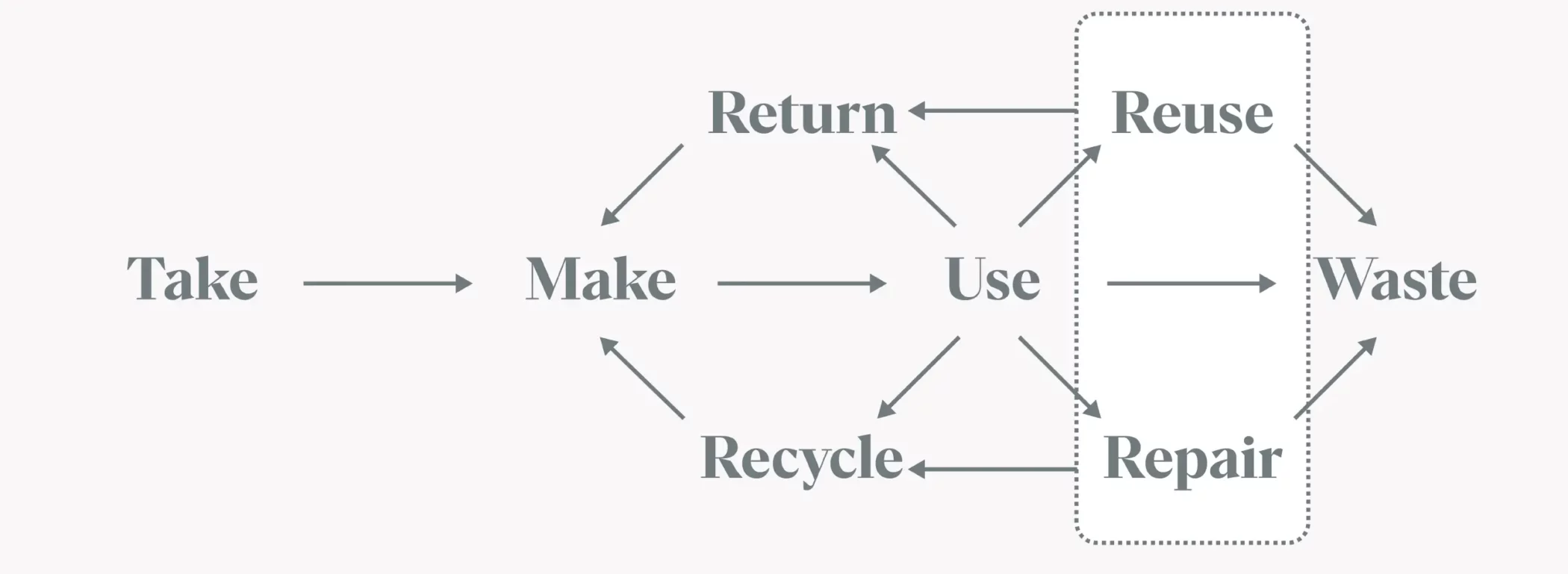

Analyzing each step of the lifecycle

Raw materials and production

Maximize the percentage of renewable energy in your production and distribution operations. Increase the percentage of products designed with recyclability and repairability in mind. This step is all about furthering the circularity of your production.

At the same time, limit the percentage or amount of virgin material input, as well as the percentage or amount of waste to landfill generated by the manufacturing process.

Return and recycle

You’ll want to up this percentage in compliance with local recycling regulations. You can do so by optimizing the amount of products and materials collected, or by increasing the purity or value of the products and materials collected. Make return points more easily available and accessible for your customers, and focus on developing a take-back program for your products.

At the same time, look to reduce the amount of collected products sent to landfill or incineration. Lower the cost of returning products, and reduce the cost of sorting and processing, as well as the time required.

Use of products

Advancing circularity starts with increasing the lifetime of products. Focus on maximizing the use of your products – just think of cars, which are only used 5% of the time. This means increasing the number of users that could share your product.

Focus on bringing down maintenance costs, while reducing the rate of value depreciation and the percentage of idle time. Minimize the amount of energy required to operate a product, as well as the associated emissions and environmental discharge. Finally, reduce your footprint by putting out fewer products.

Waste

The goal is to minimize the amount of waste products that end up in landfill, incinerated, or – even worse – discarded in nature. You’ll want to do so by increasing the number of products captured as feedstock for downstream businesses, while at the same time increasing the value of those products. Finally, you would do well to provide information on where your products ultimately end up.

Reuse and repair

When it comes to reuse, focus on increasing the value of your products on the second-hand market, and up the percentage of your products that can be upgraded to hold their value over time. Make accessibility to spare parts and repair information easier, and increase the amount of repairs carried out, while also making repairs cheaper and quicker.

Reduce the amount of discarded products and ensure that buying spare parts is financially more advantageous than buying new products.

Want more?

Turn your company’s circularity vision into a key asset for your business, while advancing sustainability across the board! Contact us for strategic advice.

There is work to do.

This is a unique challenge we would love to work on together, with you.