We help clients come up with new products, services, and processes, and recently, we’ve noticed an increased focus on sustainability innovations. While it would be lovely to claim that this shift towards social responsibility is entirely noble, the fact of the matter is that customers want eco-friendly products.

A 2018 Nielsen study conducted in the US found that products boasting sustainability claims outsell those that don’t. While the CGS 2019 US Customer Sustainability Survey saw two-thirds of respondents confirm that they consider environmental impact when making purchasing decisions and are willing to pay more for eco-friendly products.

The trouble is that there aren’t enough sustainable options available to meet demand. So what’s the hold-up? For one thing, though lots of brands claim to have recyclable packaging (despite the fact that in certain areas, the facilities to process so-called ‘recyclable’ materials simply don’t exist), they’re having trouble producing recycled packaging. This comes down not only to the low availability of top-notch recycled plastic due to the purportedly reduced quality of recycled resin (eco-responsible packaging is tricky to engineer, and different types of plastics can’t be recycled as one) but also due to concerns over food safety.

Overcoming these problems is not impossible. As this list of sustainable packaging developments proves, it just requires a bit of innovation. These companies are coming up with bioplastics and plastic-alternatives, behavior-change initiatives, re-engineered boxes, circular production systems, and more. Copy ideas for your own industry using our analogy thinking tool.

Curious to see how AI can help you come up with new solutions? Check out our blog post on 20 sustainable packaging solutions, made with AI.

Unlock the power of AI in a unique sprint format. Leverage the latest AI tools to generate new ideas, get real-time feedback, and curate new concepts to move forward with.

Configuration

Profit model

Fast-fine eateries, like modern Greek restaurant Souvla in San Francisco, are offering chef-made meals at lower prices. How? By eliminating a few steps in the chain. For instance, customers at Souvla order at the counter, rather than via waitstaff. Or they take their food to go, which requires fewer employees. Judging by Souvla’s popularity, it seems many diners will happily forego full-service in favor of a smaller bill at the end of the night.

Consumers in the US spent more than $600bn on groceries in 2018, and with the market turning towards healthier, better-quality foods, the weekly shop doesn’t come cheap. Ecommerce store Brandless has found a way around that. Brandless uses data and analytics to uncover what customers are buying. The company uses this to develop its own – often healthy and eco-friendly – versions via its website. Brandless keeps prices low by saving on marketing, advertising, distribution, and packaging costs.

Portland-based company Brew Dr. has a circular, zero-waste business model. Brew Dr. sells tea, kombucha, and distilled spirits. And the company reduces costs by connecting the production of all three offerings. The tea is used to make Brew Dr. Kombucha

Network

Competing restaurants in Xintiandi, a popular dining district in Shanghai, China, joined forces to reduce food waste and sell their unused ingredients. They combined leftover food and used it to make pizzas, called RePizzas. The pizzas come in over 200 flavors, with different options available to consumers every night.

Download our free analogy thinking tool to identify the best features from these solutions and apply them to your business.

Structure

Dutch confectionary company Tony’s Chocolonely‘s tagline is, “Crazy about chocolate, serious about people.” Capitalizing on this socially responsible brand purpose, Tony’s produces and sells chocolate using fair trade practices, while taking a stand against slavery, child labor, and exploitation by buying cocoa beans straight from farmers (and giving them a fair price) via partnerships with trading companies in Ghana and Ivory Coast.

EDWINS restaurant in Cleveland employs formerly incarcerated adults to staff its kitchen. The business gives its employees hospitality and culinary training through its leadership institute, which enables them to serve classic, high-quality French fare. The chain benefits the community by giving its team members a chance to get back on their feet and build a career.

Based in London, the Feedr platform connects corporate businesses looking for catered work lunches and functions with local food vendors. This is attractive because companies are quickly realizing the benefits of having staff eat healthily and, as a result, are wholly or partially subsidizing their food. Feedr can offer healthy catered meals for less than £5 per day, and companies like Etsy, Airbnb, DHL, and PwC chose Feedr over supplying food via canteens.

Process

Based in Rochester, New York, Farther Farms created a new technology that leverages supercritical carbon dioxide to naturally pasteurize food, eliminating the need for freezing, refrigeration, and artificial preservatives. This approach extends the shelf-life of fresh-cut produce and reduces the energy used in processing and distribution by 70%, which may have massive logistics and supply chain implications, not to mention that it could lead to superior food products. According to Dr. Syed Rizvi, professor of Food Process Engineering at Cornell University, “Such a breakthrough could be a major contributor to solving food system problems worldwide.”

Ekim

Are you ready to have your pizzas prepared by robo-chefs? French startup Ekim hopes so. The company is building 24-hour automated fresh-pizza kiosks that are each equipped with a pizza-making robot called PAZZI that can prepare a single pizza in 30 seconds. An interesting idea for transit stations and locations where people need to eat on-the-go at all hours, Ekim is also looking to serve salads, drinks, and desserts.

Pizza Hut is building a pizza-delivery car and robo-chef built into one. The company aims to reduce costs and increase speed by having the human-driven vehicle prepare and cook pizza on the way to your door. Along with minimizing the time you need to wait, this innovation has the potential to reduce the risk of your pizza being cold.

With food delivery becoming increasingly popular, ghost restaurants that are designed solely for delivery are popping up everywhere. One of these ventures is Taster. The company has a chain of online-order-only restaurants that can prepare food in five minutes and have it deposited at your door via Deliveroo in just 20 minutes on average.

AI and machine-learning platform Gastrograph AI compiles and analyzes data on the raw ingredients in the food we buy. The company uses this to help food and beverage producers predict which products customers in their target demographic will pay for. Manufacturers can see the flavors, scents, and textures consumers prefer, and develop products, optimize branding, and produce cognitive marketing campaigns accordingly.

Offering

Product performance

Love garlic but hate garlic breath? Garlidoux claims to have found a way around that. The award-winning company has removed this infamous flavor pain-point, producing a natural garlic paste that brings you the health benefits and great taste of garlic, without the nasty scent.

Startup Stixfresh has produced a sticker that is said to make fruit stay fresh 50% longer. The sticker works by creating a protective layer around the fruit. Its coating is made from beeswax and ingredients that feature a GRAS (generally considered as safe) status issued by the US Food and Drug Administration.

Consumers are increasingly interested in personalization, and PepsiCo took notice. Wanting to offer “greater choice and flexibility to consumers,” the company launched its Drinkfinity program, which enables customers to customize their own drinks by mixing pods of different flavors together with water. The pods contain dry or liquid ingredients and claim to offer different benefits. For instance, “Renew” pods contain electrolytes for hydration, and the “Charge” pods feature coffee extract.

Non-alcoholic beer sales are expected to grow substantially by 2024, with 20- and 30-somethings drinking less of the hard stuff. Catering to this market, Ceria Brewing Co. by Blue Moon offers an alcohol-free beer that provides a different kind of buzz – drinks are infused with an increasingly popular ingredient in the industry, the THC from cannabis. Heineken’s Northern California craft brewery Lagunitas is doing the same with its beer and cannabis blend, HiFiHops.

The number of people with food allergies and intolerances is on the rise, so no doubt products like Allergy Amulet’s portable food allergen sensor will come in handy. The company has developed a disposable test strip which enables you to test whether the food you’re about to eat has a potential allergen in it.

In 2018, Tufts University announced its researchers had developed a tooth-mounted sensor which could detect or measure your alcohol, sugar, or salt intake. The 2mm x 2mm sensor could be useful for medical purposes, and to enable people on specific diets to monitor and track what they’re eating.

Based in Tel Aviv, Nutrino collects physiological data from users via its platform, and with the help of machine learning and AI, recommends customized diet programs. Acquired by Medtronic in 2018, the medical device giant intends to use the service’s insights to help diabetes patients.

Though nutrigenomics – using a person’s genetics to recommend an eating plan – is still in its infancy, companies like 23andMe, DNAFit, Nutrigenomix, and Habit are all offering customized diets based on a sample of DNA. Some even offer to supply you with pre-prepped meals based on your needs. However, researchers are still investigating how much a person’s genetic makeup actually impacts their dietary needs. But some links have been drawn – certain people absorb specific nutrients better than others, for instance.

In 2020, Gatorade is set to release a sweat-sensitive skin patch that lets you know when your hydration and electrolyte levels are low by changing color. If users send a pic of the patch to the affiliated app, the app will recommend one of many Gatorade pods accordingly.

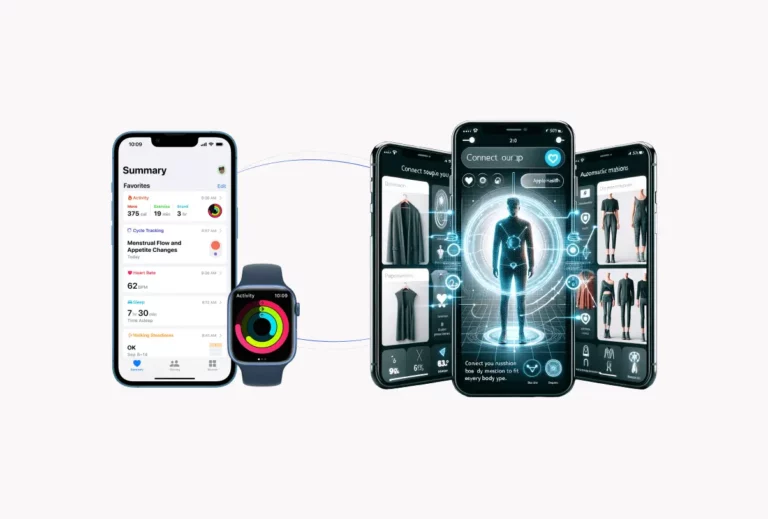

Platejoy gives users tailored meal plans based on their cooking habits and specific dietary needs, such as food allergies or intolerances. It also uses their nutritional data and information from IoTs or wearables to measure their unique energy requirements.

Digitization and robotization are impacting the diet world. FoodMarble built a device, called a “personal digestive tracker,” that can test your breath to measure hydrogen levels (which increase when food doesn’t digest properly). Via a corresponding app, it can tell you what you should and shouldn’t be eating based on how your body responds after consuming certain foods.

A major player in the at-home-testing-kit diet customization game is Viome. The company reviews each customer’s microbes via various samples to detect whether they require more of a specific supplement (because they struggle to digest it).

Beverages are becoming functional. No longer is simply serving the taste buds enough – drinks need to improve the health of customers, too. For instance, Remedy Organics infuses its handcrafted, small-batch made, organic beverages with natural ingredients that boast prophylactic properties. Ingredients like MCT oil, cannabis, mushrooms, and pre/probiotics will continue to inspire new drinks, so expect to see them on shelves near you.

Designed for convenience, French startup Feed. serves complete ‘meals in a bottle.’ The ingredients in its drinks and bars are designed to appeal to health-conscious millennials. The products are gluten-free, vegan, non-GMO, and lactose-free. And they include protein, fiber, and fats to ensure each serving delivers the same nutrients as a complete meal.

Paris-based food technology company Algama is finding ways to turn microalgae into a tasty, sustainable, protein-rich food source for daily consumption. Algama has already released SPRINGWAVE, a naturally blue spirulina-based drink that’s loaded with vitamins, and we look forward to discovering what the brand releases next.

Speaking of algae, Indonesia-based startup Evoware is putting the eco-friendly raw material forward as a plastics replacement for food packaging. Its production doesn’t require fertilizer, and it actually absorbs CO2 during growth. Evoware’s innovative edible packaging (that contains fiber, vitamins, and minerals) is used by Belgian fine waffles manufacturer Bruxelwaffle.

Having already found success (with millennials) via his plant-based food company Beyond Meat, co-founder Brent Taylor turned his sights to the fastest-growing demographic, adults over 50. Noticing the frustration felt by the age group at having been left behind by the plant-based trend, Taylor launched Perennial – a non-dairy beverage designed with older consumers’ bone, gut, and brain health in mind.

Another company turning its sights on food innovation for elderly consumers is CERELAB. This R&D center specializing in wheat-flour bread developed a protein and energy enriched brioche bun. The product has been shown to improve the health of malnourished residents in nursing homes better than the typical combination of breakfast and supplements.

Experience

Service

French supermarket chain Super U has come up with an innovative way to engage consumers who are concerned about whether the produce they’re buying is sustainable or not. Shoppers can scan QR codes on food labels via Snapchat Stories to instantly receive information about where it came from and whether it was ethically caught, farmed, or grown.

US fast-food chain Taco Bell offers convenient drive-thru service, but like many in the industry, the company is encouraging consumers to eat in-house. Taco Bell is opening its Cantinas across the US, with each location customized according to the location. They offer exclusive menus and even enable consumers to change the music. Additionally, as with McDonalds and Wendy’s, consumers have the choice of going to the counter or ordering via easy self-service kiosks.

Another chain that’s working on ambiance in order to encourage diners to eat-in (well, drink-in) is Starbucks. The Starbucks Reserve New York Roastery is a high-end 23,000 square foot space that entices customers to stick around with a full-service bar, mixology stations, an on-site coffee roasting plant, terrarium, and delightful décor.

A study by Cornell University suggests that VR can be used to enhance taste, which is exactly what Project Nourished aims to do. The company develops VR and AR gadgets and combines them with meals to give users “gastronomical virtual reality experiences.” The aim is to trick the senses by mimicking, changing, or enhancing the texture, sound, taste, and experience of eating certain foods. This tech could be used for weight management, sustainability, or to deliver weird and wonderful dining experiences.

Speaking of which, virtual reality restaurant Tree by Naked in Tokyo guides guests through meals that are meant to illustrate chapters in the journey of life. Diners are led through the experience by a narrator, with the help of a soundtrack, light show, and wind machine. And they’ll dine alongside farm animals in fine clothing – via their headsets, that is.

Channel

The Eatwith app is giving consumers unique experiences, enabling those traveling the world to not only sample the local cuisine but cook it. Via their smartphones, travelers can peruse a number of authentic cooking experiences in the region they’re visiting. Think learning to make lasagna with an Italian or fries with a Belgian.

Food waste is an issue that consumers and retailers are increasingly paying attention to. Copenhagen-based food sharing app Too Good To Go is bringing like-minded foodies and businesses together. The innovative service connects customers with restaurants who are offering up their unsold, surplus food rather than see it go to waste.

Customer engagement

Millennials are drinking less alcohol than older generations, and companies are catering to this trend. Not only are innovative non-alcoholic spirits (such as Seedlip) and beers flooding the market, but events designed to replace the booze-buzz with an exhilarating experience and opportunity for connection are emerging. One of these businesses is Club SÖDA NYC (Sober Or Debating Abstinence) – a location designed to bring together people who enjoy being high on life, and nothing more.

Brand

You know the pulp and rind that you throw away after making orange juice? Well, Italian design studio Carlo Ratti Associati is putting it to use via its Feel the Peel automated juice bar. After the juice is served, the rind is separated into a clear drum, heated, and mixed with polylactic acid to make a bioplastic which is then fed into a 3D printer. What does it make? The recyclable cups customers sip the juice from, of course.

Find out how we helped Danone create 8 product concepts for the Chinese food & beverage market.