Tell me more about this case

Let’s talk about what life needs next

Vanderlande, a subsidiary of Toyota Industries, is the global market leader for future-proof logistic process automation at airport, parcel and warehouse logistics. Their automated logistics systems move 4 billion baggages a year, 52 million parcels a day and enable warehousing to nine of the world’s fifteen largest global food retailers, including Amazon.

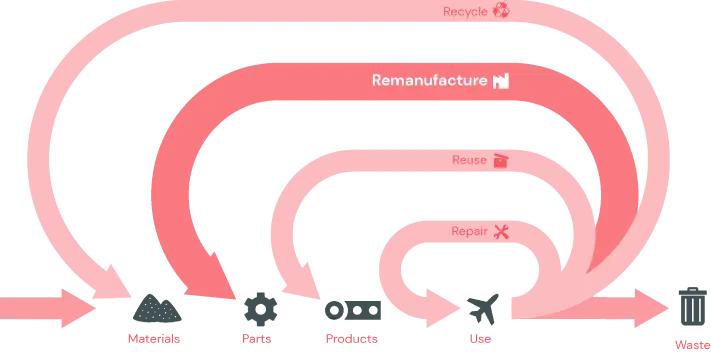

Vanderlande sought to remanufacture critical, high-value components of their automated logistics systems to ensure a steady stream of spare parts in an environmentally sustainable, profitable and reliable way. They already knew this was technically possible, but were unsure whether their customers would be interested, what the financial upside would be, and how to launch and scale this solution. They came to Board of Innovation to define how to set up the business and bring it to market.

We did in-depth B2B customer interviews with air, parcel and warehouse logistics companies that purchase Vanderlande’s equipment and identified significant benefits for them, including less downtime, increased spare part reliability and decreased inventory maintenance. We also shaped and evaluated potential business models and – perhaps most important – found surprisingly large opportunities for cost savings.

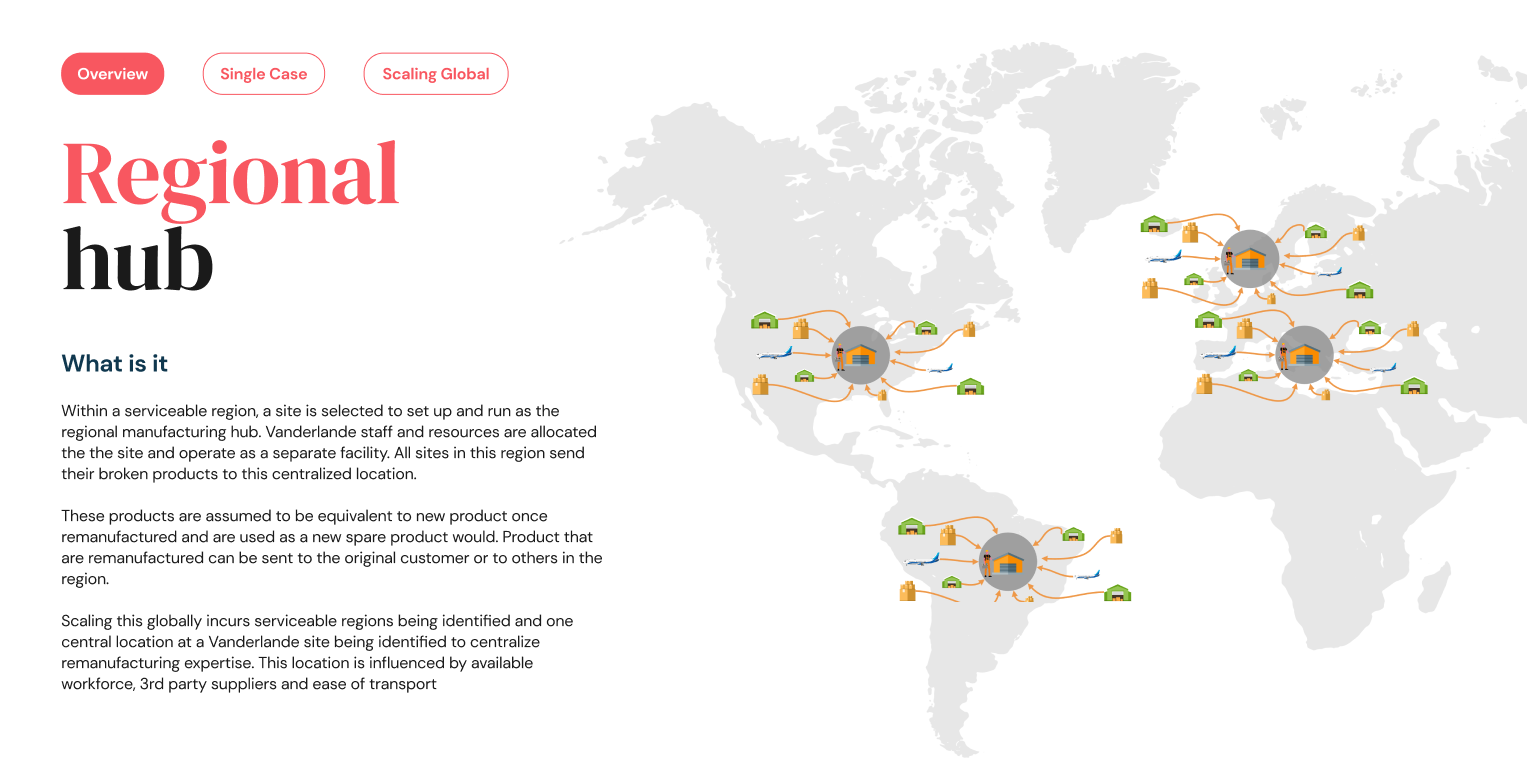

Vanderlande is moving forward quickly to pilot a regional hub system to provide remanufacturing services for its B2B customers. This should help its customers to meet their own sustainability goals as well as improve everyone’s bottom line. In the longer term, Vanderlande’s parts remanufacturing initiative could enable more local deployments of its automated logistics systems, so that we all get more kinds of stuff that we want faster and at a lower cost.

Case study at a glance – Emilie Gueissaz

Vanderlande sought to remanufacture critical, high-value components of their automated logistics systems to ensure a steady stream of spare parts in an environmentally sustainable, profitable, and reliable way. They already knew this was technically possible, but were unsure whether their customers would be interested, what the financial upside would be, and how to launch and scale the business.

By the time we started working with them on this, the company had already done enough of the technical analysis to confirm that this remanufacturing could be done at small scale; the remaining questions were whether it could be scaled in ways that made business sense for Vanderlande and its B2B customers worldwide.

We helped Vanderlande identify a way forward that appealed to all of the stakeholders in the ecosystem, with a potentially very positive impact on the bottom line. We worked with the company to identify their key customer segments and did in-depth interviews with their key customers. This wasn’t just a checkbox exercise ("What do you think about X?"); we worked to understand customer processes and journeys and to understand where the points of tension were in their operations. A popular assumption is that sustainable (secondhand, reused) things should be a bit cheaper or discounted and that's how you get people to do the right thing. But in talking with Vanderlande’s customers, we discovered the opposite was true for them: “if it works and it's environmentally friendly and I can trust you, then I'll even pay you a little more.” In part, that’s because so many of those customers, like Schiphol Airport, have their own sustainability goals, including lower CO2 emissions, and using remanufactured machinery could help achieve them.

Major Vanderlande’s customers

Perhaps the bigger business driver, however, was that spare parts remanufacturing has a positive effect on reducing operational downtime costs. This is because remanufacturing arrangements reduce everyone’s dependencies on the global supply chains for new materials and parts (which have become more tenuous), which are vital to getting machines back online quickly after technical failure. Reducing supply chain risk, and securing faster lead times for parts, allow customers to reduce their stock levels, on-site repair and inventory costs. In heavy industry, some types of OEM-remanufactured (and OEM-certified) machine parts actually tend to break less than new ones, because they’ve already survived the initial “trial-by-fire” of real-world use. This means swapping in remanufactured parts could have a long-term positive impact on system reliability and operational costs.

Internal insights customers

Working with the innovation and sustainability teams at Vanderlande, we used the BOI business model kit to map out different setups for how the company could remanufacture high value and high quantity parts at scale in ways that would make sense in terms of both a business model and what would make sense for their customers worldwide. Based on the mapping, we then identified three main scenarios for scaling Vanderlande’s remanufacturing, assessed the economies of scale and risks for each, and used existing data to project costs and revenues. One of those, a regional hub approach, with a new business model, emerged as the clear winner

In one of the final presentations of these findings, we showed Vanderlande’s Executive Director of Innovation the size of the opportunity in terms of overall cost savings. The approach we described was so tangible and these financial numbers were so large that he went straight away to the company’s CEO to let him know what was on the table. Soon after that Vanderlande decided to pilot a regional Hub in Veghel (at their company’s global HQ, where they already had engineers and space) and right now it's getting set up, with upfront pricing and letters of intent with local customers. It’s rare for action on sustainable innovation to be taken so quickly, and the momentum that this business case has generated seems really fantastic!

If the Veghel pilot is successful, the regional remanufacturing hub approach could go worldwide within five years. And the biggest change might be on product design, as Vanderlande starts to redesign the components of their systems so that they're more easily remanufacturable, including through greater use of standardized modules as they design solutions for particular purposes and customers.

Tons of CO2 reduced at scale per year

Higher productivity per employee

Faster lead time for spare parts (4 months to 4 days)

What does all this mean for airports, parcel delivery services, e-commerce companies and grocery retailers? We think they’ll have more flexibility in how they configure and reconfigure their automated logistics – for example, more flexibility to accommodate new setups in various warehouses, because their automated systems are more like assembled puzzle pieces rather than systems tailored to the original setup in one particular warehouse. And with that flexibility, they might also be able to accommodate new types of products – differently shaped or from different kinds of suppliers. That could allow all of us to have access to a broader spectrum of goods.

Let’s talk about what life needs next